This lot was a bit of a bother. They required lots of unpicking. And lots of PITA unpicking at that (because of the stretch stitch used). Hence the continuation of my Fix it marathon into July. Let’s start with the least troublesome of the lot…

1. New & Improved!

McCall 6078 Cowl Neck T

This one just needed taking in at the side seams and shortening. It was a case of:

- Picking the wrong pattern for my short-waisted torso. A loose but not flowy silhouette does nothing for my squarish upper-half. And I did have to wear this tucked in at the waist most of the time because of this second problem…

- Thinking that I can fight gravity. I had to use the stretchiest grainline for the length of the top because I ran out of fabric. It was suppose to be hip length. But it grew & grew, but not enough to pass as a dress.

2. Emami / Bradbury Endless Dress

Many-Faced Skirt

This one needed the Shar-Pei waistband/tube-bodice circu… shortened because…

- The yoga-style Shar-Pei waistband look better on a pooch than on me.

- The Mighty Weighty Skirt threatened the Tube Bodice with wardrobe malfunctioning.

I may have shortened it a bit too much. Originally I was still hoping for a Shar-Pei-less yoga-waistband wearing option, as well as a decent cowl/turleneck poncho wearing option. Needless to say that didn’t work.

In the end I had to end the Endlessness of this dress & commit to a proper waistband with elastic inside. I had a hard look at my lifestyle and decided that I’m never going to wear it as a Caped Crusading Poncho, nor as a more impractical version of Hammer Pants – imagine going to the loo in that! It’s still has some shape-shifting ability, but all are variations of skirts & apron skirts.

3. Self-drafted Bandeau Tube

Ruched Bust Top + convertible straps

This one is the diva of the batch. It demanded a piece of flesh from both 1 & 2 above. Even then, parts of it still had to be laid out on the wrong grain.

The Inspiration & Design

Yes, I seem to have a thing for ruched bust. Maybe it’s because despite my psuedo-D-cup, I still manage to look rather flat chested from the front. No push-up bra has ever managed to give me a cleavage. While the bandeau band reinforces my lack of curves, I do like this Victoria Secret ruched bust bandeau bikini top. The cinching at CF adds the illusion of a much needed curve. So I modeled my remake on this, but added a panel below to turn it into a more practical tummy covering top.

- I also added a shelf-bra with clear elastic at top (neckline) & bottom (underbust) as insurance against wardrobe malfunction. I wanted a pull over top, but I don’t trust this fabric to recover from putting on/taking off the top.

- To further prevent sagging I copied the VS inspiration & adding boning to the shelf-bra’s side seams.

- The shelf-bra has vertical bust darts which are suppose to be more supportive, but unfortunately they’re kinda visible through the top layer.

- I wanted to add bust padding for more modesty. But I couldn’t figure out figure out a way to do so without restricting the stretchability.

- I also copied the VS inspiration’s option for detachable strap. But as usual I couldn’t decide and end up with two adjustable length straps to give me more options.

The Mug & Style Shots

The Pattern

- BLOCK: Stretch Pattern School Tankini Block for Stretchy Knits (-12%/0% ease). Since I want this wearable strapless, I thought the -12% ease block based on Stretch Pattern School instruction would be safer. BTW, I just managed to tracked down the author of Stretch Pattern School (patternschool.com). He’s writing a book that will contain all the info from that now defunct site plus more. I’m waiting for info on how to get on the notification list. Will let you know when I find out.)

- Pivot side seam bust dart into CF bust dart. Pivot additional 1cm from neckline to CF bust dart to ensure snug strapless fit (like the Stretch Pattern School instruction for ‘Palette Line Maillot/One-Piece’). CF bust dart will be gathered instead of sewn.

- Establish F&B neckline, hemline, & F underbust styleline.

- Separate F bust bandeau piece at underbust styleline, but extend CF up & down for additional CF gathering. (So both neckline & underbust styline become straight lines.) Remove additional 1/4″ width at CF to increase bustline tension & prevent saggy bust ruching.

- (During fitting, I had tweak the F bottom piece’s underbust styleline because I was getting excess fabric / bagging at CF underbust. I removed the pointy bit – what would be the bridge piece in a bra. The resulting underbust styleline is straight on the F pattern pieces, but curved when sewn up as intended by the design.)

- Drafted shelf-bra per Stretch Pattern School instruction forTankini shelf-bra:

- Using the same Tankini Bloc, pivot the side seam bust dart to waist seam bust dart.

- Establish neckline (this time CF curves down to busline) & hemline (underbust line).

- Rectangles for tab to cover the CF bust gathering / ruching, and for the detachable straps.

Fabric & Notions Used

- Fabrics: All recycled from thebandeau tube + 1 & 2 above.

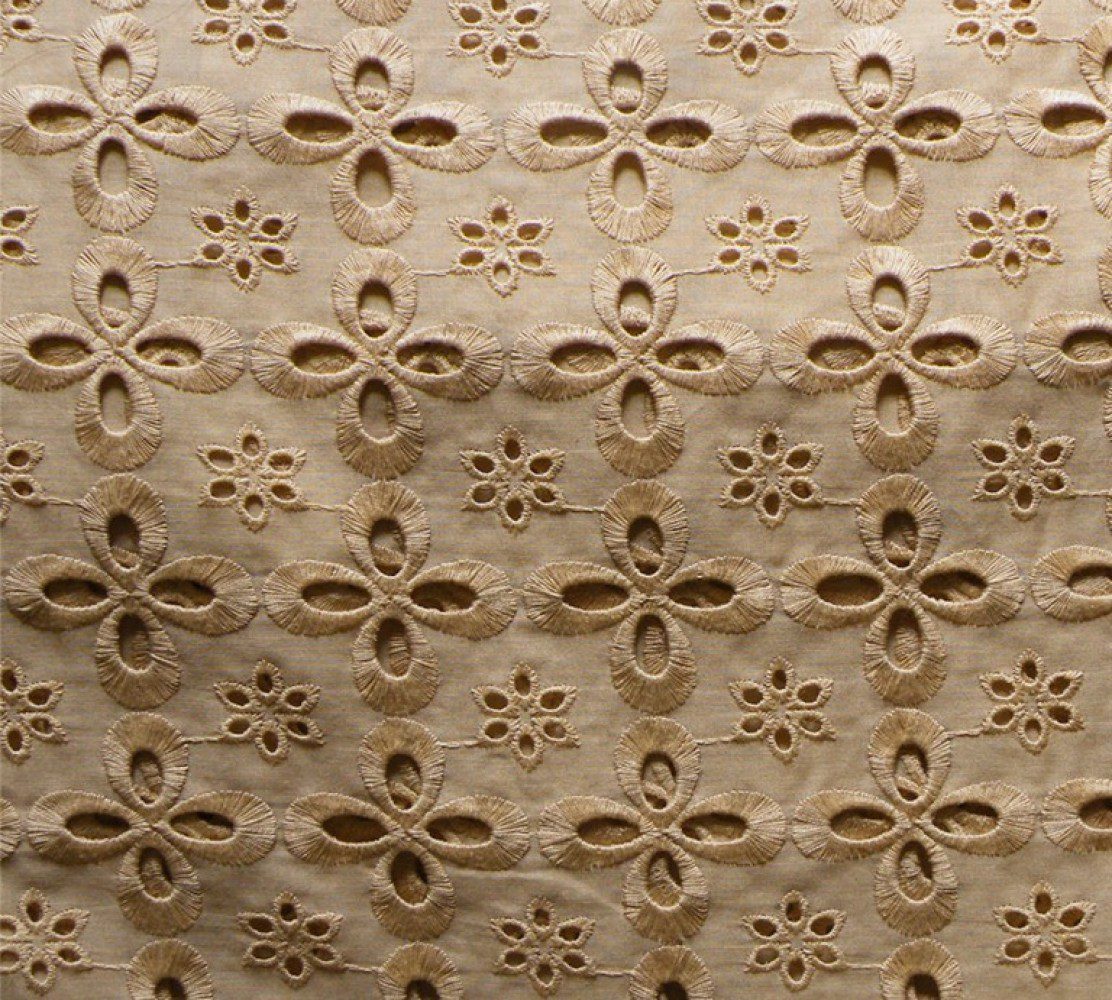

- 4-way Stretch Viscose Cotton Lycra from Tia Knight/Tissu Fabrics.

- Shelf-bra underlining: Lightweight Power Mesh from Tia Knight/Tissu Fabrics.

- Clear elastic for neckline, shelf-bra bottom, and detachable straps.

- Rigilene boning for shelf-bra side seams.

- Strap notions: Bra hooks & sliders recycled from old VS bra. Hook loops at neckline: 3/8″ Satin Woven Elastic from Pacific Trimmings.

Construction Notes

- This is my first time using Rigilene boning. It’s not recommended for corsets with require sturdier construction to keep the soft bits tightly compressed. But for a stretchy top like this I just needed a little bit of shaping, so it seems good enough. Besides, I already had it in the stash.

- To prevent the cut ends from poking I went overboard and used both options mentioned in Linda Sparks’ ‘The Basics of Corset Building’p21:

- I slid the fabric portion down a bit to expose the plastic rods. Their tips are then melted using a tea light candle. The tips didn’t actually touch the flame – they started melting when they got near the flame. I flattened the melted tips a bit while they were still warm, then slid the fabric portion back up.

- I also used scrap fabric to cover the ends after the boning has been sewn to the shelf-bra’s side seams.

- To prevent the shelf-bra from flipping out, I had to tacked its bottom edge to the outer layer at the side seams and the bottom of the CF gathering / ruching tab. The loops for the straps to hook onto are sewn on before this is done so the stitches will be hidden from the outside.

- I didn’t have bra straps in a matching color, so I had to make self-fabric straps. But as the fabric stretches in all direction, I added clear elastics inside to prevent them becoming too loose. I find this tricky as sometimes the elastic doesn’t lay flat & the strap gets a bit wavy. But once it’s on the body & slightly stretched this waviness isn’t so visible.

The Verdict

Was it worth all the trouble unpicking stretch stitches? I hope so. All three are more wearable now. Even the strapy top might be fine under a cardi or jacket for my relatively casual workplaces.

Yes, the fabrics are a bit ratty. But I like the color. And it makes the Environmentalist in me happier. We complain a bit about fast-fashion RTW being bad for the environment. But sometimes I wonder if we’re not just as bad since the process of learning to sew well may involve lots of failed projects and discarded fitting muslins. Plus the scraps from our projects might be harder to recycle especially if we sew with lots of different fibers. You don’t get the quantity of the same fabric that you’d get in RTW production waste. It makes me sad. So where possible I ‘upcycle’ my own makes despite having a huge fabric stash still waiting for their turn in the limelight.

Speaking of recycling…one of the sewing bloggers I follow (sorry, can’t find the post again for proper credit) shared a link to a fascinating documentary about an Indian community recycling our unwanted fast-fashions. It’s a short film by Meghna Gupta called Unravel. Some of these recycling ladies’ comments about the West are rather funny.

Speaking of recycling…one of the sewing bloggers I follow (sorry, can’t find the post again for proper credit) shared a link to a fascinating documentary about an Indian community recycling our unwanted fast-fashions. It’s a short film by Meghna Gupta called Unravel. Some of these recycling ladies’ comments about the West are rather funny.

Watch it on a tablet or desktop as you’ll need to read the sub-title, but on a smartphone the timeline blocks the sub-title rather than disappear like on YouTube. Very silly.